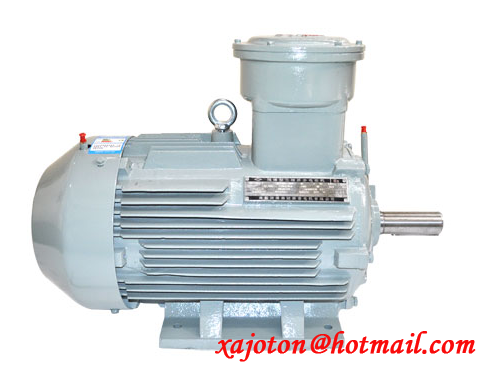

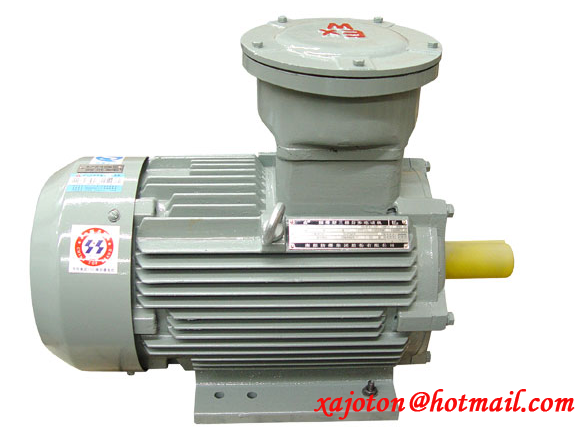

YBK3 flameproof three-phase asynchronous motor

- brand Nanyang

- model

- describe

YBK3 flameproof three-phase asynchronous motor

YBK3 series motor application range

YBK3 series explosion-proof three-phase asynchronous motor for coal mine is an axially fully enclosed self-fan cold squirrel-type explosion-proof three-phase asynchronous motor. It is a new series of mine explosion-proof motor that is newly designed and replaced by YBK3 series. It has The utility model has the advantages of high efficiency, large stalling torque, low noise, small vibration, large temperature rise margin, good performance, reasonable flameproof structure, safe and reliable use, and beautiful appearance.

The power ratings and mounting dimensions of this series of motors comply with the International Electrotechnical Commission (IEC) standards. The correspondence is the same as the Federal German Industrial Standard DIN42673. Its center height is: (100 ~ 355)

Mm; power range: (0-75 ~ 31 5) kW; synchronous speed: 3000, 1 500, 1 000, 750r / min.

The explosion-proof performance of this series of motors complies with GB3836.1-201() "Electrical Equipment for Explosive Gas Environments Part 1: General Requirements" and GB3836.2-201 0 "Electrical Equipment for Explosive Gas Environments Part 2: Flameproof Type" "", made into a flameproof type. The explosion-proof mark is Exdl Mb and is suitable for use in mines where methane or coal dust explosion hazardous mixtures are present.

The main technical parameters

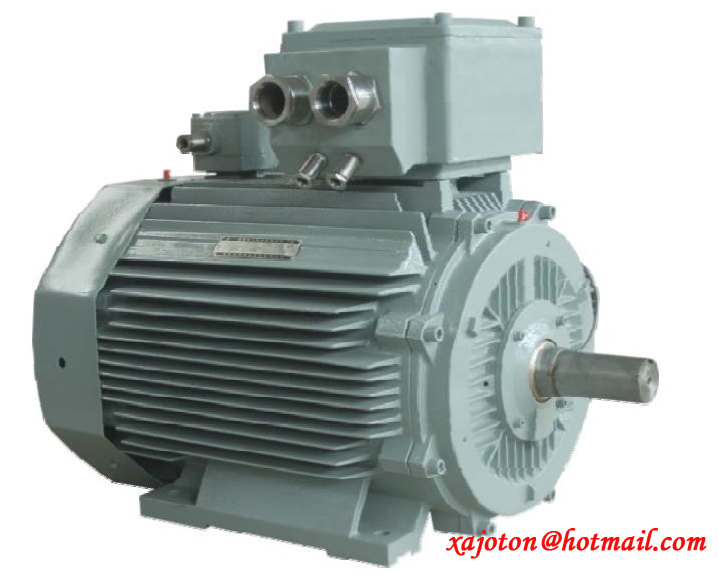

Structure description

1. The explosion-proof mark of the motor is Exd l Mb.

2. Motor structure and installation type are IMB3, IMB35, lMB5.

3. The protection level of the motor main body is IP55, and the junction box is lP55.

4. The cooling method of the motor is IC411.

5. The motor insulation grade is F grade. However, the temperature rise limit is assessed according to the B level, and the temperature rise margin is large and the service life is long.

6. The motor has a cylindrical shaft extension at one end and is driven by a flexible coupling or a spur gear.

7. The stator winding of the motor is made of high-strength polyester imide enamelled round copper wire, which is treated by VPI vacuum pressure immersion paint to form a complete whole. The winding and insulation have good electrical, mechanical, moisture resistance and thermal stability.

8. The rotor of the motor adopts the hot-sleeve process and structure of the cast aluminum rotor and the rotating shaft. The rotor is checked by dynamic balance, the motor runs smoothly, the vibration is small, and the noise is low.

9. The junction box is located at the top of the motor and is made up of six terminal blocks. The incoming line is a rubber cable structure. The four bolt through holes connected to the base of the box are set in the box cavity. The space of the box cavity is large, which not only meets the explosion-proof The procedure meets the requirements of the clearance and creepage distance of kilovolts, and can also meet the requirements of underground coal mine operation. The junction box adopts a reinforced design structure, has sufficient mechanical strength, and the connection between the terminal sleeve and the box seat adopts a thread explosion-proof structure. It has good flameproof performance and is not easily damaged during maintenance and disassembly. The locking bolt is locked with a double nut locking structure, which can reduce the local heat generated at the connection between the external cable and the connecting bolt, and improve the reliability of the connection between the external cable and the connecting bolt.

According to different starting requirements, one inlet (for direct motor starting) and two inlets (for motor Y-△ starting) can be made separately. The junction box inlet and the applicable range are shown in Table 1.

10. The main body of the motor is made of steel plate, which has high impact resistance and collision ability. The other shell parts are made of gray cast iron not lower than HT250. The end caps, bearing inner covers and junction boxes are made of grey cast iron not less than HT250.

11. The motor uses motor-specific bearings to effectively suppress vibration and noise during motor operation.

12, the full range of fans and shafts are connected by keys, reliable operation. The windshield is made of steel plate structure, the windshield is made of steel plate, and the windshield is fixed on the frame with axial limiting structure, which can withstand the impact of external force from the axial direction and obtain the maximum under the premise of preventing the invasion of foreign objects of a certain size. The ventilation area makes the wind path unobstructed. The degree of protection of the windshield is IP20.

Motor use conditions

1, the motor is suitable for electrical conditions

1.1 Rated voltage: 380/660V, 660/1 140V.

1.2 rated frequency: 50Hz.

1.3 Work quota: continuous work system S1.

2. Environmental conditions for motor use

2.1 The ambient air temperature varies with the season, and the air-cooled motor is generally 20 to +40 °C.

2.2 The altitude does not exceed 1 000m.

2.3 The maximum relative humidity of ambient air does not exceed 95% (when the temperature is +25 °C).

2.4 The motor is a coal mine underground environment.